Reconditioning services

Reconditioning of critical engine parts with laser cladding.

Laser cladding technology offers cost effective recondition service for worn out parts with shorter down-time during maintenance works.

Fast and reliable laser cladding process allows a perfect alternative to expensive new spares especially when long delivery times are considered. Laser is used in cladding as heat source to apply metal coatings. The laser beam melts the base material and metal powder to create coating layer.

Compared to welding or thermal spraying laser cladding provides a stronger metallurgical bond with minimal dilution of the base material, exceptional thickness control, and a smaller heat effected zone.

Common applications

- Turbocharger shafts and cover rings

- Pump shafts

- Piston ring grooves and fire surface

- Valves and valve seats

- Cylinder head valve seat bores

- Cast iron parts

- Bronze parts

Save up to 50-70% from the cost of new par

Delivery time from 2 days

DNV approved technology

Common applications

- Turbocharger shafts and cover rings

- Pump shafts

- Piston ring grooves and fire surface

- Valves and valve seats

- Cylinder head valve seat bores

- Cast iron parts

- Bronze parts

Save up to 50-70% from the cost of new par

Delivery time from 2 days

DNV approved technology

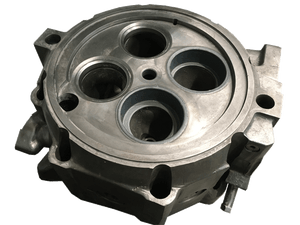

Cast iron parts reconditioning

Common issues

Sealing surface is worn out, damaged or chipped off. Corrosion is found on critical parts. Certain dimensions reached oversize limits preventing further repairs.

Solution

Custom reconditioning solution will be based on thorough examine result of working conditions and specifications of the cast part. Would it be stainless steel, superalloys or bronze – laser cladding process has virtually no limits.

Benefits

Prolong the lifetime of cast parts enhancing its original wear and corrosion resistance. Save up to 70% compared to the cost of new parts. Shorter down time due to the speed and high availability of the laser cladding process, which might not be the case with original spares supplies.

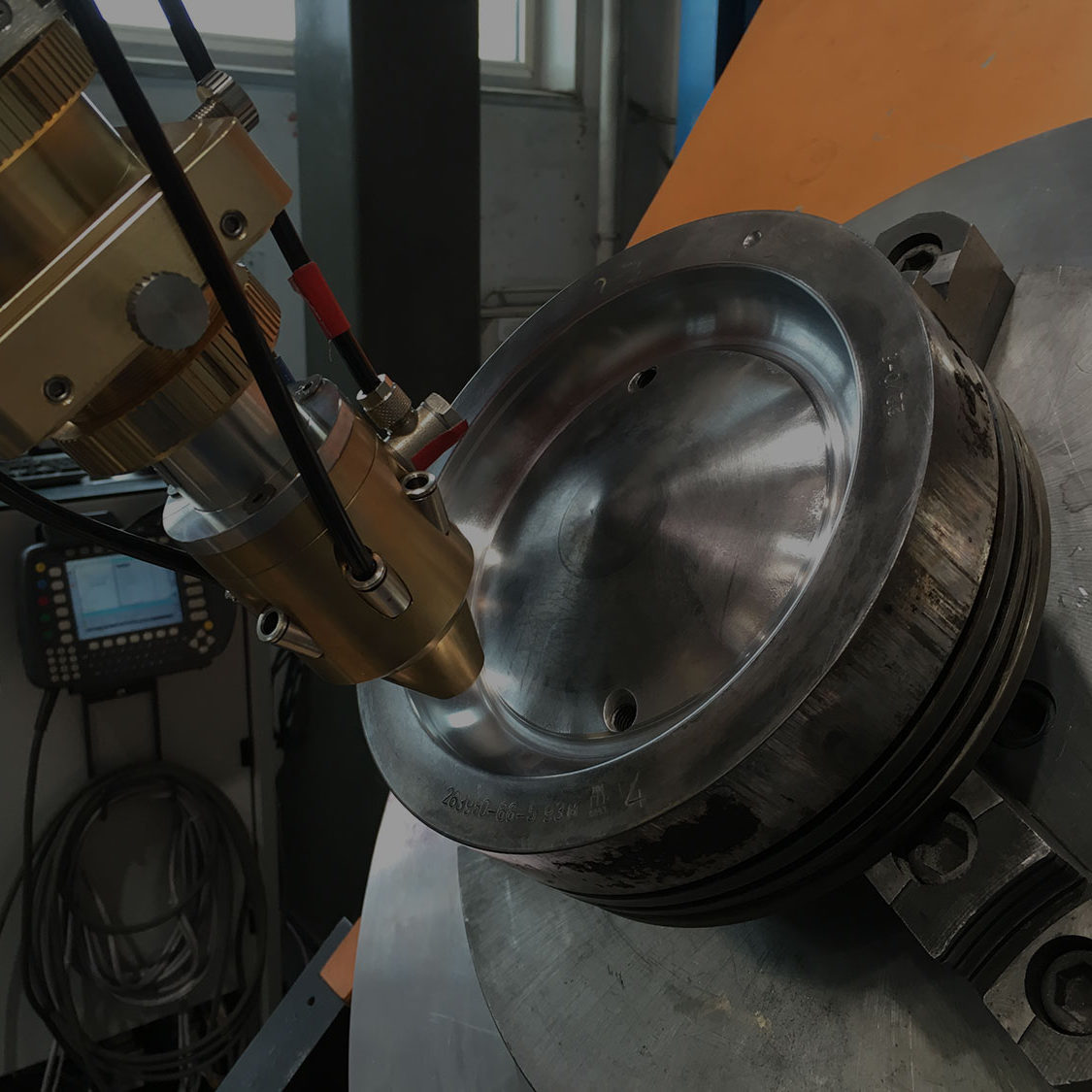

Piston reconditioning

Common issues

Piston ring grooves over the limits. Excessive erosion of the fire surface.

Solution

Piston ring groove reconditioning with Stellite cladding, which by its properties excels original chromium layer and reduces wear. Fire surface cladding with superalloy Inconel is well suited for service in extreme environments exposed to heat, pressure and corrosion.

Benefits

Prolong the lifetime of the piston enhancing its original wear and corrosion resistance. Save up to 70% compared to the cost of new parts. Shorter down time due to the speed and high availability of the laser cladding process, which might not be the case with original spares supplies.

Before & after

Before & after

Piston reconditioning

Common issues

Piston ring grooves over the limits. Excessive erosion of the fire surface.

Solution

Piston ring groove reconditioning with Stellite cladding, which by its properties excels original chromium layer and reduces wear. Fire surface cladding with superalloy Inconel is well suited for service in extreme environments exposed to heat, pressure and corrosion.

Benefits

Prolong the lifetime of the piston enhancing its original wear and corrosion resistance. Save up to 70% compared to the cost of new parts. Shorter down time due to the speed and high availability of the laser cladding process, which might not be the case with original spares supplies.

Before & after

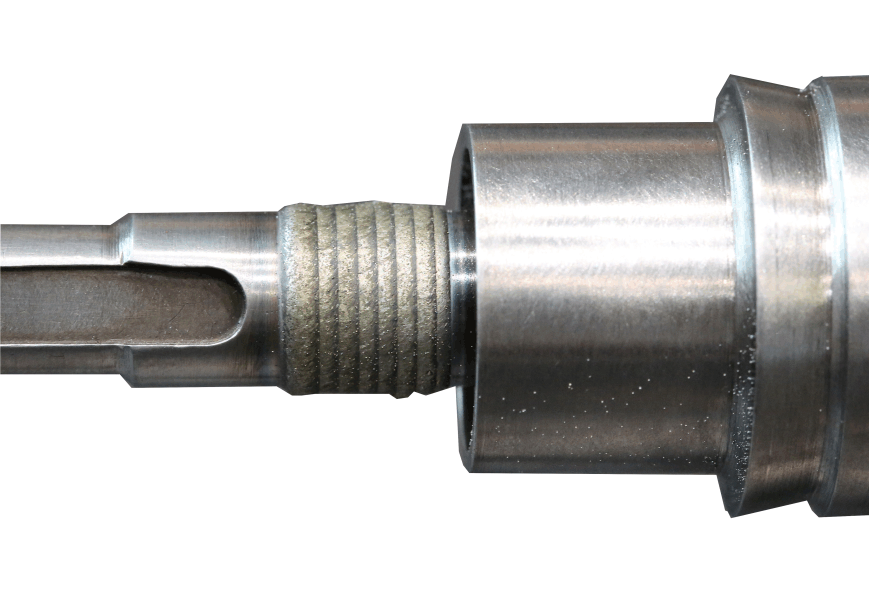

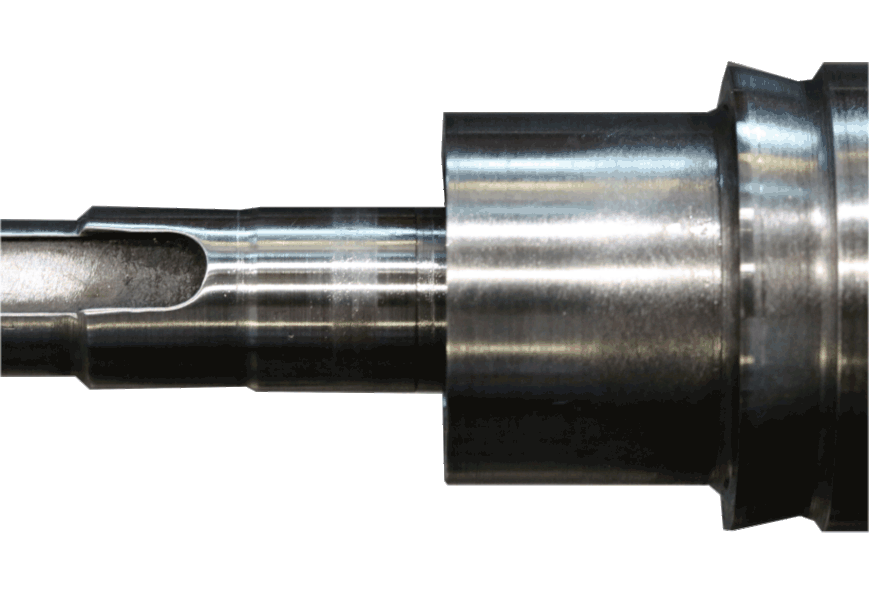

Turbocharger reconditioning

Common issues

Rotor bearing journals are worn out. Sealing ring grooves are over the limit. Cover ring diameter meets no-go criteria.

Solution

Laser cladding with superalloy Inconel is well suited for service in extreme environments exposed to heat, pressure and corrosion. This allows to recover turbocharger parts back to OEM specifications.

Benefits

Prolong the lifetime of the turbocharger parts enhancing its original wear and corrosion resistance. Save up to 70% compared to the cost of new parts. Shorter down time due to the speed and high availability of the laser cladding process, which might not be the case with original spares supplies.

Before & after

Turbocharger reconditioning

Common issues

Rotor bearing journals are worn out. Sealing ring grooves are over the limit. Cover ring diameter meets no-go criteria.

Solution

Laser cladding with superalloy Inconel is well suited for service in extreme environments exposed to heat, pressure and corrosion. This allows to recover turbocharger parts back to OEM specifications.

Benefits

Prolong the lifetime of the turbocharger parts enhancing its original wear and corrosion resistance. Save up to 70% compared to the cost of new parts. Shorter down time due to the speed and high availability of the laser cladding process, which might not be the case with original spares supplies.

10313 Tallinn

Estonia

+372683 3340